About IWRTC

- International Waste Research & Technology Centre is a Division of Envergy Projects Ltd. & it is engaged exclusively in developing cleaner processes, technology for waste reduction, recovery, recycling and reuse of Industrial, Urban , Rural, Agricultural , e-wastes in India & abroad.

- The focussed area is to identify opportunities with 5 Rapproach as Reduction, Reprocessing, Reuse, Recycling & Recovery of wastes.

- To convert the Hazardous wastes into a non-hazardous commercially viable products or by-products, alternative fuels, with application of green chemistry in processes and resources conservation

- To apply LCA approach to the whole processes & develop route for better & optimised resources.

- Green Chemistry & CP are the mantra for IWRTC

IWRTC Infrastructure & Approvals

International Waste Research & Technology Centrehas in-house state-of –art R&D Laboratory & Pilot Plants with following certification & accreditation at Vadodara(Gujarat),India:

- MoEF & CC recognised & Gazetted Environmental Laboratory under EPA 1986

- NABL/ISO 17025 & OHSAS 18001 Accredited

- ISO 9001,14001 & 450001 Certified Organisation

- GPCB Approved Environmental Laboratory

- RPCB Approved Environmental Laboratory & Environmental Consultants

IWRTC Research Laboratory

GCI Laboratory have state-of-art analysis Facilities for Physical, Chemical, Microbiological & Environmental Testingequipped with following in struments:

- GC

- AAS

- UV-VIS Spectrophotometer

- Flame Photometer

- LAF, Autoclave, Microscope

- ORSAT apparatus

- Bacteriological Incubators

- BOD incubator

- Bomb Colorimeter

- Melting Point Apparatus

- Flash Point Apparatus

- COD Digester

- Pilot Plants for in house Treatability studies.

Jar test apparatus

Fume Hood

Experts & Expertise

- IWRTC has multidisciplinary experts & expertise to dealing & expertise to dealing with the complex problems of Hazardous & Non-hazardous Wastes with educational background of Science, Engineering, conomics with wide experience.

- Pradeep Joshi, Managing Director & Group President with 35+ Years experience in Sustainability solutions in India & abroad

- Nachiket Joshi, Director Finance with 15+ Years’ experience in Account & Finance.

- Suhas Deosthali, Associate Vice President (ProcessEngg.), 36+ Years experience in Process, Operations & Engineering

- Dilip Bhosale, Assistant Manager- WtR & Sustainability with 9+ Years’ experience in Solid & Hazardous Waste Management. & team of 132+

Wastes Research & Technology Development Scope

Industrial

Hazardous & Non-hazardous wastes such as :

- Spent acids / solvents / catalysts / alkali / carbon

- Waste oils, sludge from ETP, Process & Residue

- Residues & Distillates

- Salts & Evaporator Rejects

- Boiler Ash

- Process , ETP & Paint -Sludge

- Mining waste

- Textile & Leather Urban & Rural

Urban & Rural

- MSW / Glass / Metals / scraps / e-wastes

- Agricultural residue / rejects

Bio-medical wastes & Other wastes

Wastes Research & Technology Development Scope

- Process & Operation study to understand how & why the waste is generated

- Sampling & analysis of wastes (Qualitative & Quantitative assessment)

- Pre-feasibility study at Lab level

- Pilot studies & Preparation of PFR & DPR including Market Research and Legal compliance for Waste to Product/Energy Projects

- IWRTC offers end-to-end solution with performance guarantee for the technology including plant basic & detailed engineering design, supply, erection & commissioning, operational support with technology license and operations support.

IWRTC Services

Transforming International Waste Research & Technology Centre & Energy

- Waste (solid & liquid)–Sampling & Analysis

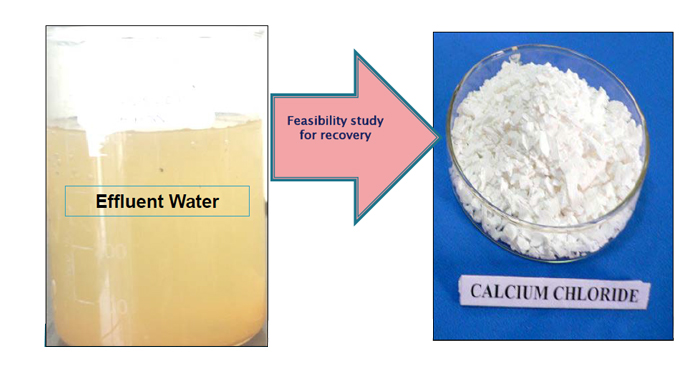

- Treatability & Feasibility study

- Waste Audit of the facility

- Process & Operation study for identifying waste 5 R approach

- Waste Footprint

- LCA

- Water Audit & Footprint

- Energy Audit

- MSW / Glass / Metals / scraps / e-wastes

- Agricultural residue / rejects

- Cost Reduction/optimisation studies through Waste Reduction

- Recovery of Heavy & precious metals, solvents from effluents & sludge

- Spent catalyst & Carbon-reactivation & recovery

- Alternate Packaging Materials & Alternative fuels study

- Green chemistry application in manufacturing

- Waste to Product & Energy feasibility & pilot plant studies

- Zero Waste program-implementation & training

- Contract Research

- Analytical Services for air, water, waste water ,Wastes & Soil testing/analysis

- Policy Research

- Legal Permit/Compliance from MoEF/CPCB/PCB

- Pre coprocessing / Co processing to AFR for cement plants

- Waste-to-Energy Projects.

- Waste-to-Resource Recovery Projects

- Hazardous Waste Rule-9 Application

- Hazardous Waste Sending for Co-processing

- Consulting for hazardous wastes management

IWRTC Services

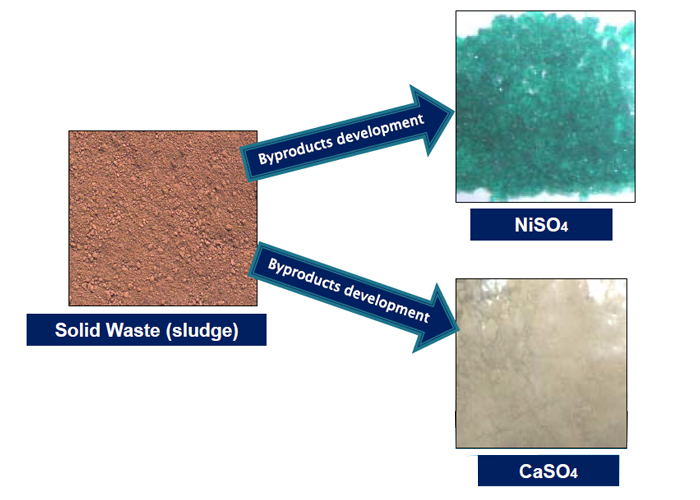

Nickel Recovery from sludge

- With 5% Nickel in the pickling plant sludge, the Ni is extracted as Nickel & complex as Nickel sulphate, Chloride, etc

Converting waste to Micronutrient

- In a manmade fibre manufacturing the ZnSO4 is converted into a micronutrient which is blended nitrogenous fertilizer

Residue is converted to alternative fuel

- The residue has good GCV & now it is used for furnace

Spent carbon is reprocessed - The spent carbon is re-processed & used again

IWRTC Projects Services

- Hazardous Waste Pre-Processing Facility for Cement Co-processing

Pre-Processing is defined as pre-treatment of waste streams coming from different sectors and industries to make it suitable/homogenized for feeding into the kiln system to avoid process fluctuations. Preprocessing involves only physical transformations like size reduction (By Shredding and cutting), separation of foreign/undesirable materials (magnetic materials separation by Magnetic separator, use of metal detectors to remove metallic particles and desired size selection (Size selection by screening operation, manual size selection by handpicking of large material size on very low speed Belt conveyors).

- Effluent Spray Dryer ( High COD & High TDS ) & Secure landfill

- Spent Sulphuric Acid to Gypsum Manufacturing Facility

- Spent Hydrochloric Acid & H2SO4 Regeneration Facility

- Drum , Barrels & IBC -Decontamination/Reconditioning/Washing Facility

- Metal’s Recovery Plant from Hazardous Wastes

- Foundry Sand Reclamation Plant

- Biomass Briquettes (Clean Fuel) Manufacturing Plant for Boilers/TFH

- Waste Plastic To Sheet & Pavers Block Man

- Used/Waste Oil Re-refining Plant

- Transformer Oil Recycling Plant

- Solvents Recovery Plant (SRP)

- Battery Recycling Plant

- Waste Plastic To Fuel Oil (Pyrolysis) Plant

- Plastic waste Granulating/Recycling Plant

- Integrated Municipal Solid waste management (Bio-gas, Bio-CNG, Organic Manure, Waste to Energy, RDF plant, MRF Plant, Methanol Plant)

- Bio Medical Waste Incinerator

- E-Waste Recycling Plant

- Organic Waste Processor.(OWP)

- Hazardous Waste preprocessing Plant (AFR) to Cement Coprocessing Plant

- Spent carbon Regeneration Plant

- Prefeasibility Project Reports, -Detailed Feasibility Project Reports-Detailed Projects Reports.

- FRP Recycling Plant

Case Studies-1

Case Studies-2

Way Forward

- If you have any hazardous or non-hazardous wastes ,send your sample to our R&D Laboratory for preliminary assessment.

- Send us your brief about the wastes (solid or liquid) as follows (only for proposal) :

- Quantity generated

- Chemical composition (IWRTC can do this on chargeable basis)

- Requirements

- Current disposal practices

- Any legal requirements specific to the waste under consideration

- We sign Non-disclosure agreement (NDA) with you

- We analyse the sample ,conduct pre-feasibility and with positive results a full fledge feasibility & recovery/recycling /treatment system is developed with CP principle

Summer / Project Training

IWRTC offer students from universities / colleges summer training / internship / project training programs including support to PhD students for their Research projects in Environmental Laboratory at Vadodara (Gujarat), India from abroad & India, interested institutions can email their details to hr@gccipl.net or call Cell + +919377430557 for needful.

IWRTC offers students from universities /colleges/ working professional Skill Training Course programs including support to PhD students for their Research projects in Environmental Laboratory at Vadodara (Gujarat),India from abroad & India, interested institutions can email their details to info@envergy.co.in or call Cell ++91 9824272844 / 9898246340 for needful.

Skill Training Course

- Industrial Hazardous & Non Hazardous Waste Management

- Municipal Solid Waste Management

- Waste Management Technologies

- Municipal Solid & Hazardous Waste Management

- Hazardous and Other Wastes (Management and Trans boundary Movement) Rules, 2016

- Municipal Solid Wastes (Management and Handling) Rules, 2000

- Plastic Waste Management Rules, 2016

- E-Waste_(Management)_Rules-2016

- Construction and Demolition Waste (C&D)_rules_2016

- Bio-medical_Waste_Management_Rules_2016

- Battery management & handling rules 2001

Transforming waste into opportunities

A Global Initiative for the Cleaner Processes & Advancement of Waste and By-product Research

International Waste Research & Technology Centre

ENVERGY PROJECTS LTD.

Green Empire, (Anupushpam),Gotri Rd.,

Vadodara-390021(Gujarat),India

Web: www.envergy.co.in Email: iwrtc@envergy.co.in

Cell: +91 84859 73889 / +91 98258 22564

Our Clients

- M/s. Pidilite Industries Ltd.

- M/s. Shuddhi Industries LLP.

- M/s. Banas Resource LLP.

- M/s. Vishay Components India Pvt. Ltd.

- M/s. Multi Organics Pvt. Ltd.

- M/s. Abhideep Chemicals Pvt. Ltd.

IWRTC Profile Jan2022

~ PDF (401KB)